| Sign In | Join Free | My webtextiles.com |

|

| Sign In | Join Free | My webtextiles.com |

|

| Categories | DTF Hot Melt Powder |

|---|---|

| Brand Name: | Tunsing |

| Model Number: | DS220 |

| Certification: | RoHs, REACH |

| Place of Origin: | Shenzhen,CHINA |

| MOQ: | 20kg |

| Price: | negotiate |

| Payment Terms: | T/T, PayPal |

| Supply Ability: | 6000kg per day |

| Delivery Time: | 5-7days |

| Packaging Details: | 1kg per bag, 5kg per bag, 20kg per bag |

| Density ASTM D-792: | 1.20±0.02 g/cm³ |

| Melt Point: | 90-115 ℃ |

| Hardness: | 80±3 Shore A |

| Powder size range: | 80-200 μm,100-200 μm,150-250 μm |

| Other names: | TPU Powder |

| Type: | hot melt adhesive powder |

| Company Info. |

| Shenzhen Tunsing Plastic Products Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Heat Transfer Printing T-Shirt Printing White Hot Melt Transfer Tpu Powder Dtf Powder

Activation Mechanism: The activation mechanism of DTF TPU Adhesive Powder involves heat and pressure to melt the powder and create a strong bond between the design on the transfer film and the target substrate. Proper activation ensures a permanent and durable transfer.

Layering Techniques: Advanced users may employ layering techniques

with DTF TPU Adhesive Powder to enhance the opacity, color

vibrancy, and durability of the transferred design. Layering can be

used strategically to achieve specific visual effects and improve

adhesion on challenging surfaces.

Special Effects: Some DTF TPU Adhesive Powders are formulated to

create special effects such as glitter, metallic finishes, or

textured surfaces when transferred onto fabrics. These formulations

add a unique and eye-catching dimension to printed designs.

Wash Resistance: High-quality DTF TPU Adhesive Powders are designed

to withstand repeated wash cycles without compromising the

integrity of the transferred design. The adhesive properties ensure

that the design remains vibrant and intact over time.

DTF TPU Hot Melt Powder Physical Characteristics:

| Property | Criterion |

| Appearance | White powder |

| Composition | TPU |

| Density ASTM D-792 | 1.20±0.02 g/cm³ |

| Melting Point DSC | 90-115 ℃ |

| Melt Index ASTM D-1238 | 28±8 g/10min |

| Hardness | 80±3 Shore A |

| Powder size range | 0-80 um,80-200um,150-250um |

| Resistance to yellowing (level) | 2.0-3.0 |

DTF Powder Application

Sportswear and Activewear: DTF TPU Adhesive Powder is commonly used in printing on sportswear and activewear due to its flexibility and durability, which are crucial for garments that require frequent movement and washing.

Customized Accessories: The adhesive powder is applied in creating

personalized accessories like bags, hats, and footwear, providing a

reliable bonding solution for adding custom designs to these items.

Specialty Printing: DTF TPU Adhesive Powder is utilized in

specialty printing applications that require a strong and

long-lasting bond, such as in creating custom patches, emblems, and

branding elements for various products.

DTF Powder Technical Parameters:

Bonding Parameters ( reference only) | Temperature | 140-160℃ |

| Press | 1.5-2.5 kg/cm2 | |

| Time | 8-15 S | |

| Washing Resistance | 40℃ | Excellent |

| 60℃ | Good | |

| 90℃ | / |

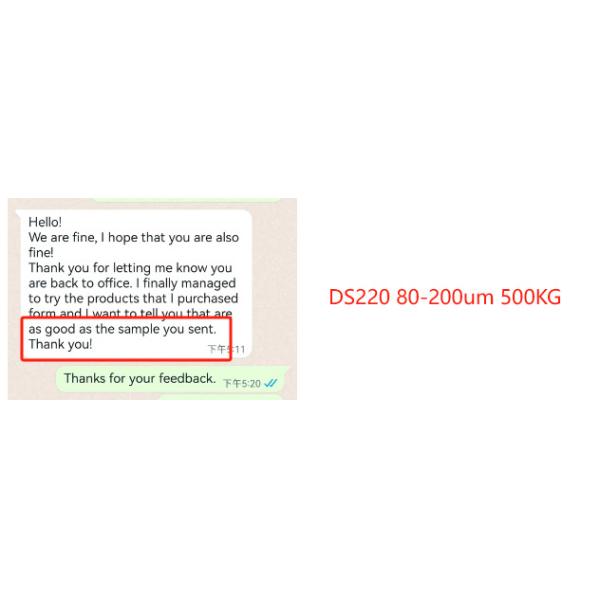

DTF powder Customer feedback

|