| Sign In | Join Free | My webtextiles.com |

|

| Sign In | Join Free | My webtextiles.com |

|

| Categories | Automated Dispensing Machines |

|---|---|

| Brand Name: | Chuang wei Dispensing machine |

| Model Number: | CWDJ |

| Certification: | Ce Certificate |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 1000 sets per year |

| Delivery Time: | 5 work days |

| Packaging Details: | plywood case |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Work area: | 300X*300Y*100Z mm |

| Max. load(Y/Z):: | 7kg/3kg |

| Move speed(X&Y/Z): | 400/200mm/sec |

| Repeat accuracy: | ±0.01mm/axis |

| MOQ: | 1 set |

| Company Info. |

| Dongguan Chuangwei Electronic Equipment Manufactory |

| Verified Supplier |

| View Contact Details |

| Product List |

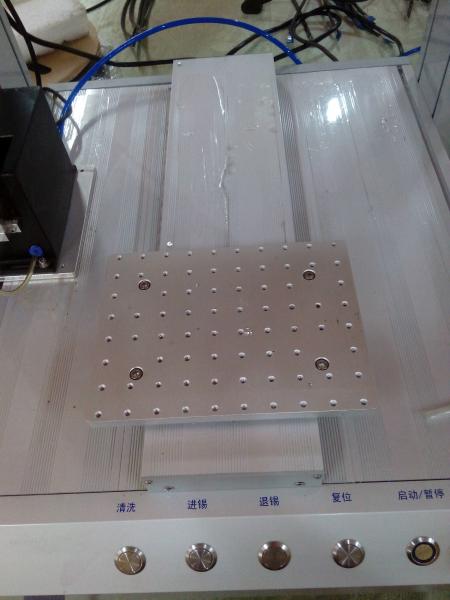

High precision glue dispensing machine

Applications :

Dispensing Robot

1 , LED package

2 , Mobile phone plate coating or dispensing button

3 , Speaker Dispensing

4 , Dispensing sealing the battery case

5 , The semiconductor package

6 , Power component package

7 , chip binding Dispensing Robot

8 , Fixed and protected PCB electronic components

9 , LCD glass board package

| Technique Specifications | |||

| Model | CWDM-2 | CWDS331 | CWDS221 |

| Process range | 400 / 400 / 100 | 300 / 300 / 100 | 200 / 200 / 100 |

| Max Load(Y/Z) | 10 kg/ 5 kg | 6 kg / 2 kg | 4 kg / 2 kg |

| Speed of motion | 0.1~600 / 250mm/s | 0.1~600 / 250mm/s | 0.1~600 / 250mm/s |

| Positional Accuracy | 0.02 mm/Axle | 0.02mm/Axle | 0.02mm/Axle |

| Repeated Accuracy | +/- 0.02mm/ Axle | +/- 0.02 mm/ Axle | +/- 0.02 mm/Axle |

| Storage | Control Card 16MB Extended Storage 2 GB | Control Card 16MB Extended Storage 2 GB | Control Card 16MB Extended Storage 2 GB |

| External Communication | SD Card | SD Card | SD Card |

| Displayer | LCD | LCD | LCD |

| Driving method | Step motor + Timing belt | Step motor + Timing belt | Step motor + Timing belt |

| Programmable Graphic | Point, line, circle, arc, continuous line, etc. | Point, line, circle, arc, continuous line, etc. | Point, line, circle, arc, continuous line, etc. |

| Double Y axle | Upgrades Available | Upgrades Available | Upgrades Available |

| Edit mode | Demonstration | Demonstration | Demonstration |

| I/0Signal | 24in / 22out | 24in / 22out | 24in / 22out |

| Power source | 220V(+/-10%/50Hz) | 220V(+/-10%/50Hz) | 220V(+/-10%/50Hz) |

| Visual positioning | None | None | None |

The automatic dispenser machine can satisfy various requirements

for dispensing , only need to choose different fixtures and math

with dispensing systems .

The following installation instruction is based on the 30CC needle

cylinder clamp and simple type dispensing system as a model .

1 . The standard accessories include the 30CC needle cylinder

clamps , and they can be applied to 30CC or 55CC needle cylinder .

If you want to use other needle cylinder , then you have to

purchase other needle cylinder clamps appropriate .

2 . Fix the needle cylinder clamps onto the Z axle . Put the

hexagon socket flat head screws through the holes of the clamps and

then lock on the Z ground side . The clamp has a couple of holes to

select , according to the specific requirements .

3 . Connect the signal port ( three holes ) of the dispenser

machine on the backside to the signal port in the controller with

dispenser signal line . The signal port in the dispenser machine is

the same one that connecting with the foot-plate . Thus a problem

may appear that the port can not be shared , if your dispenser

machine is not purchased along with the matching machine . In such

case , please contact the Extruder supplier for joint exchanging .

4 . Connect the compressed air source to the dispenser controller ,

put the needle cylinder collet onto the needle cylinder and tighten

it , and put the needle cylinder into the needle cylinder clamps

and lock the screws which are used to fix the needle cylinder . (

Please don’t over tighten , in case of deformation . And once it

deforms , the piston then cannot fit with the inner side of the

needle cylinder, and cause air leakage . )

5 . Connect the handheld programmer to the machine .

6 . Connect the dispenser machine and the controller to 220V power

source .

7 . Do make sure the pressure pipe of the needle cylinder collet

and the power source will not influence the motion of each axles

and working plate .

8 . Congratulations for completing primary set of the dispenser

machine , please learn teaching mode operation according to the

following chapters .

Features :

1 , Could be a particular dispensing operations, mechanized production

2 , Simple and convenient to operate, high-speed precision

3 , Program files can be uploaded / downloaded through U disk ,

easy to manage

4 , Has control buttons on the needle , no external teaching is

more convenient than similar products debugging

5 , Used LCD 5-inch color screen display Dispensing Robot

6 , Does not cause noise pollution to production sites

7 , Enabling 3D dispensing systems , regardless of any comple shape

and dispensing path can be accurately completed

8 , Can be equipped with single-tube or pipe dispensing , improve

efficiency in the realization of different glue or dispensing path

9 , Used for in all kinds of demand dispensing industry , such

as:general common UV plastic , silicon , EPOXY, red gum , paste ,

AB glue ,

COB vinyl , conductive plastic , aluminum heat glue , instant glue

, paste and other points glue , can be used on the D-series devices

.

Details technical parameters :

Advantages :

1. English LCD panel teach pendant, easy operation and learning.

2. Three axis movement robot has the function of drawing points,

lines, surfaces, arc, circle, irrecular curves consecutive

interpolation.

3. Dispensing volume, dispensing speed, dispensing time, stopping

dispensing time can be set.

4. Autmatic curving protection.

5. Special dispensing controller makes fluid flow stable without

leaking and dripping.

Our Services :

1. Stable quality, competitive price, one year free parts warranty

except for dispensing consumables, such as plastic pipes, needles.

Over the warranty, lifelong maintenance is also available with some

charges.

2. One week delivery after down payment for standard type.

|